Content Table

Introduction

7 deadly wastes that suck cash from your business.

Content Table

Once you know what these wastes are, you can uncover them and minimise them, saving your business money. Money saved due to waste reduction goes straight to improving your bottom line.

What is Waste

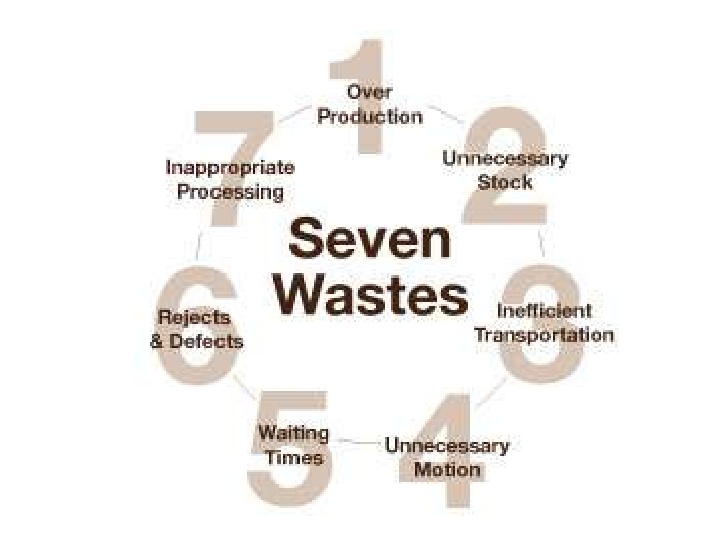

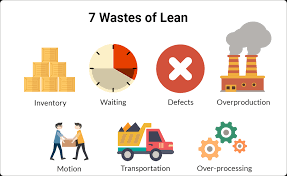

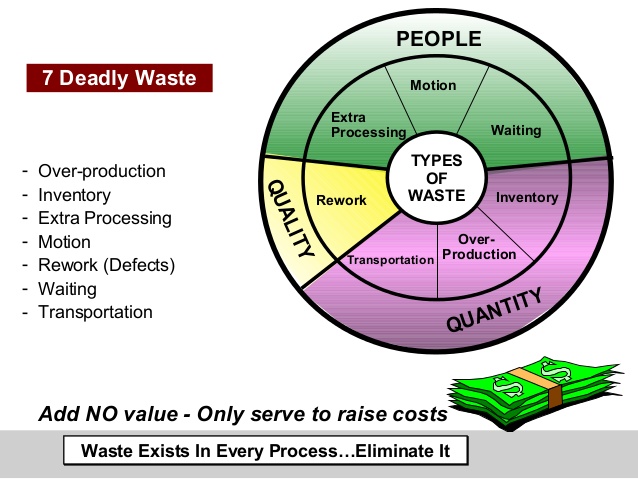

The Seven Wastes of Lean Manufacturing and Their Impacts on the Environment. … Under the lean manufacturing system, seven wastes are identified: overproduction, inventory, motion, defects, over-processing, waiting, and transport.

Content Table

Eliminating waste is at the heart of the Lean Business methodology. The goal of Lean is to spend more of your time creating value for customers by reducing or eliminating everything else – the waste. Several common types of waste have been identified and together represent the “7 Wastes of Lean” (sometimes expressed as “8 types of waste, including the additional “waste of human potential” or “waste of talent”).

Some types of waste are fairly self-explanatory, but others can be a bit difficult to grasp. Here are some practical examples of each.

Gallery

Different types of waste

Content Table

Video

How to remember waste and tackle them

Content Table

8

Your Score

Best Book

A book that helps you identify the 7 deadly wastes that suck cash from your business. Written by a six-sigma black-belt and world renowned trainer.

PROS

- Quick read on Muda

- Refresher for people who want quick look

CONS

- No

Where to Buy

Online purchase