PDCA Cycle is four-stage approach for continually improving processes, products or services, and for resolving problems

What is PDCA?

PDCA was popular by Edward Deming who is considered to be the father of Quality Control. This concept is based on the scientific method. “hypothesis-experiment-evaluation” or as “plan-do-check”. This scientific method is showing us – Once we find the gaps after completion of one cycle, execute the cycle again will extend the knowledge of the process. Repeating the PDCA cycle will bring the results which we want to achieve.

Before starting we want to give one example – You are providing a Medicine service and you are having a good business. But now your customers in particular area has started to complain that you’re on time delivery is poor hence they are avoiding taking a service from you. In this situation you are using a supplier to provide the medicines directly in the particular area. Who can provide service faster and with in timeline. Now you’re pleased to see that the feedback from customer is positive. As a result you have decided that for particular area you will go through direct supply to the customer. What you have done to close these gap that is called “PDCA”.

https://en.wikipedia.org/wiki/PDCA

This approach is based on the belief that our knowledge and skills are limited but if we complete each cycle properly, our knowledge gets improving and ultimately will go closer to the desired goal.

Plan

Decide the goals based on the process requirements, projects, customer requirements including resources required / responsibility & timeline of the particular activity. Can be use timeline sheet for monitoring purpose.

DO

Carry out the activity as mentioned in the plan.

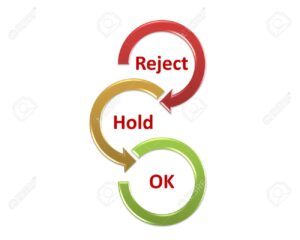

Check

Check the % of the results as per plan. Find out the gaps / issues which you have been faced. Do the gap analyses or evaluation to get the actual result.

https://shivconsultancy.org.in/quality-management-system-iso-9001-7-principles/

Act

Find out the solution based on the identified problems. Make a lesson learnt & take a corrective action.

If not get the result in one cycle then repeat it till get the results. Definitely you will go closer after completion of one cycle.

What is the Importance

PDCA is an iterative. This four step approach for continually improving processes, products or services and for resolving problems. If we are facing any problems in the business, in the system or in the sales growth etc. We need to go through this cycle honestly to find out the problems and analyze the steps. It will provide us the solutions that we needs to implement to get the desired results.

https://shivconsultancy.org.in/quality-management-system-in-business/

Where it can be use

- Quality Management

- Process Management

- Change Management

- Continuous Improvement

- Implementation of the new projects

- Process Performance Management

- Organizational Competitiveness

- Supplier Management

If you want to improve your business processes or wants to get certified for the standards. Please contact us for consultancy services.

Please visit our website for further details –

+91 9892815919 / 7218963881